|

|

|

|

Can I drive my alternative fuel vehicle (AFV) in high occupancy vehicle (HOV) carpool lanes, regardless of the number of passengers?

The simple answer is "yes"in some states. The use of AFVs in HOV lanes is addressed in Section 102 (a) of title

23, United States Code. The following states have provisions that allow AFVs in HOV lanes: AZ, CA, CO, DC, GA, UT, VA

|

|

|

THE ABC'S OF FUEL ALCOHOL

How much does it cost to produce 1 gallon of ethanol?

It will cost about $1.10 to $1.20/gal to make

the alcohol from various feed-stocks like corn, barley, potatoes, or Jerusalem artichokes. You will also have by-products

which you can sell or use as animal feed, reducing the total cost down to about $.95/gal.

Or, you can make it the cheap and easy way for only $1.20/gallon on a large scale, buying molasses by the ton

(if it is a high sugar molasses). See my page on Molasses and Rum.

What materials are required to make ethanol once I have a still set up?

First, you need a good source of feedstock.

By feedstock, I mean a good source of sugar or starch (carbohydrates) which can be fermented in the same process as which

you make beer or wine. You aren't going to drink it, so it can be somewhat contaminated: For example, we once made a batch

from a weeks' garbage from a low-security prison (one of our CAPFA founders worked there), so he separated it out for

us. It was mostly lumpy mashed potatoes and stale bread, and we had to fight off the flies while we ran mixed it with water

and dumped it into a larger fermentation tank. Then we covered it with window screen to keep the flies away.

Another

time we used 5 year old dehydrated prunes, which I soaked for a week to get them soft enough to grind by hand, with a baseball

bat. Realistically, you want to do all this on a farm where you have access to hammer-mills, large tanks, and various means

of handling large amounts of feedstock (and the resultant waste). Corn (dry kernels) is one of the best, as it is over 70%

starch. Also,you can use sugar beets, Jerusalem artichokes, rotten apples, grape skins from a winery, and much more. Molasses

works great, too.

3. Can you buy a car already set up to run on Ethanol?

There are lots of cars you can buy that

are already set up for E-85: Ford Taurus, Chrysler Voyager Minivan, Ford Explorer, dodge Ram pickups and Mazda 3000 pickups,

and much more. Go to my web page, "Converting your Engine" and click on the photo of the Sebring convertible to find out which

cars are already factory-ready for E-85 fuel, which you can make yourself.

4. How much feedstock does it take to produce one gallon of ethanol?

180-proof is 90% pure ethanol. To make it, start

out with something cheap and readily available to make your own beer. I suggest you start with ordinary corn, wheat or barley,

and start by following an ordinary recipe for making beer at home. Corn is best, with more starch. Grind it with a 1/8th inch

screen mill (if it is too small, it is like flour and will ball up in water, so a course grind is better). For starters, use

two 50-pound sacks of grain (40 kg). (I don't suggest buying this on a regular basis, but just for your first run if you dont

have anything else available for free).

If you make 80 litres (20 gallons) of beer at a 10% alcohol content (which is about what you get working with corn) you

end up with a little over 2 gallons of high proof (.10 x 20 gal/.9 = 2.2 gal of 180 proof).

In metric, this is .1 x 80 ltr/.9 = 8.9 litres.

You will soon discover that for making fuel, you will want to start with a minimum of 100 gallons,

hopefully at a 10% sugar concentration, to get 10 gallons of fuel to be efficient. This is not a project for the your kitchen,

as it will get a bit messy, Better to do it in the garage.

5. Does ethanol have a shelf life, and will it lose

its octane level like gasoline does?

If it is sealed, it will last for years and years. If opened to the atmosphere, it

will suck moisture out of the air and get a little bit diluted.

6. Isn't ethanol bad for certain fuel system components in fuel pumps and carbuerators?

No. Todays cars are built to be compatible with ethanol-blended fuels. When ethanol was first introduced in the 1980s,

some cars experienced deterioration of some elastomers (rubber-like parts) and metal fuel system components. Very quickly,

manufacturers upgraded their fuel systems so that today, they are now all compatible with ethanol fuels. 7. Can you make

ethanol out of straw, grass clippings, or wood chips? Yes and no. Alcohol is now being made from straw by a Candian company,

Iogen, which is using a genetically modified organism (GMO),in this case,yeast to do just that. See my page on making Ethanol

from Straw.

http://www.alcohol4fuel.com/id37.html

But this yeast product is not for sale and certainly will not be available to small scale producers. Other techniques have

been tried--I even have a 25 year old book on making ethanol from sawdust-but they tend to be expensive, dangerous (involving

strong acids) and have toxic waste products.

8. Can your still be used to make methanol? Isn't methanol a better fuel than ethanol, which is why it is used

for racing?

No. Methanol or "wood alcohol" was made in the 18th and 19th Century by "destructive pyrolysis", which is burning wood

chips inside a closed chemical retort container in the absence of Oxygen. This process used 15 times more energy than contained

in the end product of methanol, but they were interested in the methanol for other purposes, such as for paint thinners and

other chemical needs. Actually almost any still will have small traces of methanol along with the high proof ethnanol. The

triple distilling action of the Charles 803 still that I use, will remove most of the methanol, but that doesn't mean it is

safe for drinking. If you want to build a still for drinking alcohol, there are a lot of smaller and cheaper stills you can

build. The Charles 803 still is for making moderate quantities or ethanol for use as a fuel. You can make 5 to 8 gallons an

hour of 180 proof. If you want to sell your fuel, this is probably too small a still for you, but it is nevertheless a good

tool for learning about fuel productions and for experimenting with different feedstocks for fermentation. The thing is, you

don't need super pure alcohol if you aren't drinking it. But for the sake of your engine, it is quite good to have high proof,

triple-distilled alcohol as made in the still I designed. You may not have removed the all the methanol, but this is a good

fuel, and burns clean. The fusil oils and various other impurities have mostly been removed, but any minor impurities

will also burn, much cleaner than gasoline, with no carbon build-up. In fact, ethanol will dissolve build up carbon as it

burns, so the end result is a clean engine.

Now, as for the question, which is a better fuel, ethanol or methanol, ethanol is clearly the better fuel: it has 38% more

available energy (86,000 BTU's per gallon for ethanol, while methanol only has 62,000 BTU's/gallon). Methanol is commonly

used for racing as it is a cheap and easily available byproduct of the Natural Gas industry, and is cheaper than ethanol because

they don't have to pay the distillation taxes. Ethanol is also used in racing, and the Indie 500 has used this fuel for over

80 years, now. Ethanol is less corrosive than methanol, and burns very clean, with only CO2 and water as the main byproducts

of combustion (there is a slight amount of aldyhides in the exhaust, but it is 300% cleaner than burning gasoline.

Polishing the reflux section in preparation for soldering

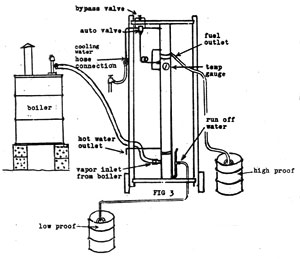

This simple diagram shows a boiler sitting on concrete blocks, with a safety vent at the top of the boiler. The hose routes

the hot steam into the bottom section of the three-stage still, with the internal reflux and cooling coils. The high proof

alochol drains out into the glass bottle.

Molasses & Rum

Vegetable oil to replace diesel? Here is an article from a speech I gave in 1994 to the Colorado Seed Grower's Association

on the use of vegetable oils as a fuel to replace diesal.

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQ)

How do I start?

Q. Where can I get plans for an ethanol still? A. Blueprints and instructions are available for the Charles 803

ethanol still that will make 5 gallons or more an hour of 180-proof ethanol on the first run, every run. It is only 5 feet

high and weighs only 28 lbs (13kg). This is an advanced fourth-generation design. It is not a toy for making drinking

alcohol: this is a serious tool for making your own fuel. The blueprints are available from the designer, Robert Warren,

former founding director of the California Alcohol Fuel Producers Association (CAPFA), a non-profit organization dedicated

to promoting alternatives to using petroleum fuels. Robert has constructed 130 to 140 working stills, and he has taught

hundreds of people how to build stills and make their own fuel alcohol. His research on ethanol spans 25 years, and he was

a founding member of CAPFA. Q. Can I make this still myself? A. Yes -- if you are handy with copper plumbing

tools and techniques. You'll find the blueprints and written instructions to be quite thorough in helping you through all

parts of assembly. The instructions are very precise and include photos to show you the whole assembly process. But it helps

if you have an experienced hand to solder the pipes properly.(Get a friend to help you). The instructions include material

on how to solder properly--This is a relatively easy and satisfying thing to learn. The plans contain the complete

list of materials, detailed drawings of the construction procedures, and some alternative methods of heating and running the

still. It also includes several pages describing how to adjust and run the still, with variations for different feedstocks

and fuel sources. Q. How much do the blueprints cost? A. US $30, or 20 Pounds Sterling (UK). Allow one

week for delivery by post. Printing is the main cost, and batch-printing keeps the price down. You will get the blueprints

via normal post within one week, and I email 40 pages of text with color photos, usually within 24 hours. You get everything

from how to build the still, how to build the boiler, and how to run it. (not available on web site). From anywhere

in the world, you can order these still blueprints by credit card through Paypal. This provides a safe and secure way

to order the plans and download the files immediately. Go to "Contact us" or to my home page, and click on the PalPal

icon. Q. How much will the still cost to build? A. It will cost you about $400 to $600 to build the

still-- less, if you're good at scavenging parts and components, tanks, boilers, old plumbing fittings, etc. You can scavenge

a lot of the other materials on the materials list, but if you want the still to work right, you need to build it exactly

as shown on the blueprints. This is a fourth-generation design, and it is very efficient. You'll need 5 feet of 3-inch-diameter

copper pipe, with various copper fittings from a plumbing supply store which are listed in the plans, costing around $125

to $150. The key piece of technology is the automatic temperature sensor/controller valve, which precisely regulates

the optimum temperature for separation of condensed alcohol from the water vapors. This ensures consistent production of 180

proof ethanol. There are two types: the automatic valve, non-electric, costs $330 including shipping. We also sell a less

expensive electronic kit version for $180, which includes a programmable controller with an LCD temperature display, themral

sensor with copper adaptor to install inside the distillation column, and the solenoid valve for controlling water temperature.

Either valve can be purchased by going to the "Contact Us" page. An old gas water heater can be cannibalized for the gas

burner, if you want to use propane or natural gas to heat your boiler to run the beer through the still. Or you can make a

wood burner out of some concrete blocks and an empty 55-gallon oil drum turned on its side. Use scrap wood for fuel.

Q.

How long will it take to build the still?

A. I used to teach a still-building class over a two-day weekend, which

included a full day of building and completing a still. It may take you a month just to get all your components together,

and then you can put it together in one or two good weekends.

Invite a friend over to help. Soon, you'll want to have

a still firing event with your friends showing off your new state of the art still! Nothing makes you feel more self-reliant

than running a car, motorcycle, or even a lawn mower on fuel you've made yourself!

Q. What's the production rate?

A. If you have 50 gallons of beer at a 5% alcohol content (which is about what you get working with barley or

wheat) you end up with a little over 5 gallons of high proof (0.05 x 50 gal / 0.9 = 5.5 gal of 180 proof). With dry corn,

you can easily get twice as much alcohol from the same amount of grain. It takes about an hour to get this beer up to boiling temperature, and just a little over an hour to distill it.

So, if you count just what comes out of the still once your boiler is running, you get about 4.5 to 5 gallons per hour

of high proof!

You can see that to be efficient you will want to start with a minimum of 100 gallons, hopefully

at a 10% sugar concentration, to get 10 gallons of fuel.

If you run the still at full capacity (it is designed to

handle a 500-gallon boiler), you can produce 5 to 7 gallons per hour of 180 proof fuel.

You can even run two stills in parallel if you want 14 gallons per hour. You don't want a large batch to go

bad because you didn't get around to distilling it, if you aren't fully set up for running the still. So, start small and

know what you are doing before trying to ferment and run large batches. Q. How much does it cost to produce 1

gallon of ethanol? A. If you do this on a large enough scale, it will cost anywhere form $0.95/gallon to $1.40/gal

to make the alcohol, depending on your feedstock. Look at my web pages, "Mashing and Fermentation" and also, " Molasses and Rum ". You will also have animal feed by-products which you can sell to reduce the total

cost by another $0.40/gal. Q. What do I do once I have a still set up? A. First you need a good source

of feedstock, that is, a good source of sugar or starch (carbohydrates) which can be fermented in the same process with which

you make beer or wine. You aren't going to drink it, so it can be somewhat contaminated. Waste fruit from a supermarket

trash bin can be a reliable, on-going source of fuel! Another good source is a commercial bakery. Realistically, it's

best to do all this on a farm where you have access to hammermills, large tanks, and various means of handling large amounts

of feedstock (and the resultant waste). Feedstocks: corn (stocks, cobs, and all, preferably not dried) are good,

as are sugar beets, jerusalem artichokes, rotten apples, grape skins from a winery, and much more. As for fermentation,

this is basically the same process as for making beer or wine, except that you don't have to worry about the taste, since

you aren't going to drink this stuff. More information on feedstocks and fermentation can be found on Mashing and Fermentation. Q. Is it easy to learn how to make ethanol? A. It's not rocket science, but there is quite a lot to learn.

Running a still does require some knowledge of the whole process. You really need to read a couple of books on the subject,

which may or may not be out of print. Go to my page on Making Scotch Whiskey. This gives you the basics, plus I have some

good links on that page. There are some good resources at the Journey to Forever website, at this link. http://web.archive.org/web/20001017131055/http://journeytoforever.org/ethanol_link.html

We'll be adding more and more resources on all aspects of ethanol production -- not just links, but full-text information.

Before too long you'll be able to find everything you need to know right here. Q. How corrosive is ethanol to fuel

system parts and how have you addressed this problem? A. Ethanol is somewhat corrosive to certain rubber and cork

materials found in older cars with carburetors. But new cars built in the past ten years are made with new materials that

are unaffected by ethanol, since it is now found in over 30% of the gasoline we buy. Look at my page on making your own E85.

Of, if you start with an old car, take the carbuerator apart and soak various parts in some white lighting for a few days.

Look for signs of deterioration and replace what you have to. Ethanol may also eat the coating inside most older

gas tanks, so a separate plastic cross-link polyethylene tank is recommended (but not necessary). I just put my

alcohol in a standard gas tank and then clean the fuel filter occasionally. If you make your own E85, and your car is listed

as a flexible fuel vehicle (2 million American cars per year are now made this way) then you have no worries. Q. How

do you combat the problem of hard starting on cold days? A. If you are making your own E85, I suggest you make E50

for winter and Spring use, and only make E85 when it doesn't drop below freezing temperatures at night. On old cars, our most

common method is to salvage an old windshield washer pump from a junk yard and rig it up so you can push a button on cold

mornings to squirt a small shot of gasoline into the carburetor. Q. What is the octane rating of 180 proof ethanol?

A. 180 proof ethanol is equivalent to 106 octane. You would need to modify your engine to run a fuel that is 90% alcohol

and 10% water. This involves carburation (or fuel injection) and timing. But if you buy or own an E85 car, these adjustments

are done automatically, due to a new computer chip and Oxygen sensor in the fuel line. Q. What engine modifications

are required? Perhaps none at all--the car you drive may already be factory-ready for E-85 (85% ethanol) which you can make

yourself. A. In the old days (pre-1990), engines had carbeurators, and you had to drill out the jets or install larger

jets. Go to my page, "Converting your engine" for instructions on how to do that. We are setting up a network via

this website to get new computer chips made for cars that need them, and a list of cars that already have the right chips.

(These computer chips adjust the fuel injection and timing accoring to an O2 sensor that tells it what fuel blend you are

using. If you change the chip (a quick under-the-dashboard type thing_ keep the original so you can to revert back to gasoline.

Convert your engine.

In several vehicles I've owned, I never changed the jets at all: I just pulled out the choke a little bit. This

allows you to change the air-fuel mix to where it sounds best and runs good. Don't let any of this stop you -- we need

to get people out there making their own fuel and showing the oil giants that we aren't dependent on their whims. The newer

engines have an O2 sensor and a computerized controller that automatically adjusts the fuel injectors to the type of fuel.

If you go to the "Contact Us" page, you can read the ongoing discussions and suggestions from those who have actually built

this still and are sharing their knowledge on engine modifications with the rest of it. If you yourself are a certified mechanic,

we welcome you to contribute to these discussions. Q. Does ethanol have a shelf life and will it lose its octane level

like gasoline does? A. If it is sealed it will last for years and years. If opened to the atmosphere, it will suck

moisture out of the air and get a little bit diluted. Q. Does ethanol go rotten in time like gasoline and produce

varnish? A. No. Alcohol is what preserves your wine and gets better as the years go by. But you need to start with

triple distilled alcohol as made in the still I designed so that the fusil oils and other impurities are removed. But you

must keep it sealed, as alcohol is hygroscopic--this means it will suck the moisture out of the air. So keep it capped so

it doesn't get diluted. Store it in glass, but plastic milk bottles are quite stable and the alcohol will keep OK. Q.

How difficult/expensive is the US licensing process for making alcohol? A. Getting a licence from the Bureau of Alcohol,

Tobacco, and Firearms (BATF) is not difficult, and only takes about a month. Go to my page, Is it Legal? and right at the

top, there is a link to the form you can print out and mail it in.

In other countries, such as the UK, you may find that making your own alcohol is very much illegal. Q. Is there

a limit to how much ethanol can be produced for individual use? A. In the USA, you can make as much as you like. (You

will have less hassle if you tell them you are applying for the small scale production plant of less than 10,000 gallons per

year). The only requirement is that you report how much you make and that you denature it (make it poisonous to drink). Isn't

that a strange way of making sure people don't drink it? They must think it is better to kill folks than to let a few people

get off without paying the tax. This law was established back in the days of prohibition. Q. Do you have any similar

information on butanol? A. Butanol is a pretty exotic fuel, not something you want to make in your backyard, as the

smell is truly horrible -- not so much the fuel itself, but the cellulose-eating bacteria, like very smelly socks times 1,000!

Butanol is a very interesting fuel, though, as it can be made from rice straw which is normally just burned off, and you don't have

to modify your engine as it is completely compatible with gasoline, as well as miscible (it will mix with) with gasoline.

Better to stick with building a still and making ethanol. It is clean and there is no pollution, and the neighbors

won't complain about the smell. I have more information and links on Butanol on my Other Biofuels page. Q. The part

of the process that concerns me is the mashing and fermentation. Is there any way to simplify or automate these stages? A.

The California Department of Agriculture ran a still-building competion a few years back and awarded a prize to Floyd S. Butterfield,

a farmer who automated pretty much the whole process. He used sludge pumps to circulate the mash during the fermentation and

also the cooking processes, which keeps the solids from stacking up at the bottom of the cooker and burning during the process

of boiling (cooking) the mash to create the steam vapors you are feeding into the still. There's a detailed report

on the design and performance of Mr Butterfield's Farm Still here.

There are lots of books about commercial alcohol production, but you may have to go to an agricultural university library

to find them. The enology (wine making) department at Univerity of California, Davis is a world leader in the field and has

extensive resources on ethanol production, as does the California Department of Agriculture. How does it work? See:

Principles of Operation

PRINCIPLES OF OPERATION

|

|

|

|

|

|

|