|

|

|

|

Backyard ethanol

You can make fuel alcohol in your backyard, and many

people are doing just that, and running their vehicles on clean-burning alcohol instead of gasoline.

You'll need a

still, and you will need to ferment beer, or wine, from corn, barley, kitchen scraps, or even molasses. You can build your

own still. We have excellent information available to help you learn what you need to know. Follow the links....

|

|

|

If you have been looking for a true reflux still, this is it! Reflux refers to the up and down action inside the still where

the alcohol and water vapors are condensing and re-boiling, as it this process that successfully separates out the pure alcohol

from the water. There are many still makers out there who say they have a reflux column type still, and they do not even know

the meaning of the word!

Most of them make the biggest mistake made by many generations of still makers: they have

the reflux column and condenser permanently attached (and therefore thermally coupled) to the boiler. This means that the

only way to control the temperature (which is what controls how high the proof is) is by means of raising or lowering the

temperature of the boiler. Perhaps in a laboratory or in your own kitchen, burning propane or natural gas (and thus, burning

fuel to make fuel), this can be somewhat controlled. This works OK for making small amounts of drinking alcohol, but if it

is fuel your are after, you want to burn scrap wood, or anything you can get cheap or free as a fuel source, because you have

to minimise your costs and also be adaptable.

Controlling a boiler pot is a huge bother, and nearly impossible.

This is why my still has the distillation column as a separate and easily controlled discreet component.

With

a pot still, on the other hand, once the beer solution gets hot enough to boil, it starts to boil fast. At this point, a mere

5 degree (F) change in the temperature of the vapors will result in the final product being only 100 to 120 proof instead

of 160 to 180 proof. To get high proof ethanol, you have to be able to control the temperature accurately and quickly within

a very narrow 1 degree Fahrenheit range. This is only possible if you physically separate the reflux column from the boiler.

Secondly, you have to include an automated control method, such as the automated temperature control valve pictured on my

still (located just above where my friend has his hand resting on the left side of the still).

Most home-made

stills you will find on the internet are not true reflux still as there is rarely enough internal surface area or thermal

mass to stabilise the alcohol vapors to create the turbulent up and down effect of condensing ethanol dropping down and being

reheated by upward vapors and a the same time cooling and stripping the ethanol out of the upward-moving vapors. A reflux

column needs to be internally packed with a thermally stable packing material. The large reflux columns in a commercial still

use ceramic marbles or rashig rings typically.

PRINCIPLES OF OPERATION

|

| The top section is the condenser section. |

Robert Warren has built

over 140 of these stills, and this design has evolved over many years with quite a few highly skilled engineers assisting

in the process.

To order the still plans, from anywhere in the world, click

on PAYPAL, below, for a secure credit card transaction. As a result of many requests for this hard to find item, we have decided

to offer the automatic temperature control valve, in addition to the alcohol still plans.

Still Plans: Hard Copy $30.00 (US) or 20 pounds Sterling

(UK)

You get blueprints sent by post and 40 pages of detailed instructions and photos sent to you by email.

Contact Us

|

|

|

|

|

|

|

|

|

| Robert Warren in Boulder running his still. |

|

| The placard at the top is my BATF alcohol still licence. |

Robert Warren's still

Robert Warren has built 134 alcohol fuel

stills -- this is number 131, in action at an energy fair in Boulder, Colorado, in 1992:

"I had organized a

pretty big energy fair, as part of a larger Renaissance Fair. We invited another ethanol enthusiast to bring over his VW Rabbit,

which he had converted to ETOH for a total sum of about $20.00, and we ended up the weekend, filling it with the ethanol we

produced at the fair.

"I also got someone from the National Energy Research Laboratory to bring over and show one

of their $30,000 car conversions: a brand new, fuel injected multi-fuel Chevrolet Lumina, which could run on gas, ethanol,

or methanol.

"We even had some students from the University of Colorado bring over their photovoltaic racer which

had a couple of months earlier participated in the coast-to-coast Solar Challenge.

"This particular still is a very

efficient design. It has an automatic temperature control valve, and graduated heat loss via internal water cooling, both

of which are keys to consistent proof. It produced 180-proof ethanol on the very first run! It can make 5 gal/hour of 160

to 180-proof, which is a great fuel."

I called a couple of local breweries, because I had been in the hospital only

the week before, so I didn't have time to brew up some mash on my own. Boulder Beer donated 60 gallons of fresh beer, in two

30 gallon plastic drums. With the help of a friend, I poured 30 gallons into the 50 gallon metal drum which was supported

in a cradle made from another 50 gallon drum which I had "carved" with a cutting torch into a convex shape. I had also scooped

out huge air holes for the combustion oxygen needed by the big cast iron propane burner I had scavenged from a very old water

heater. I also removed the guts of the pressure regulator on the water heater control valve, as I wanted to be able to turn

it way up on high because I wanted boiling water, not just hot water. The cutout barrel support stand was set on top of two

concrete blocks, as I had to keep the fire and the heat from the burners well off the grass. I had learned this the hard way

by leaving a burned circle on a University lawn a few years, before. I also kept two fire extinguishers handy: not so much

because I thought I would need them, but I did have to apply for a special permit from the local fire department in order

to run the still. It is so crazy how everyone gets so worried about flames near high proof alcohol, when actually, it has

a much, much lower flash point than gasoline vapors. Making alcohol is a relatively safe and clean operation.

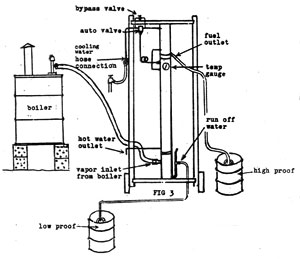

You

can't really see it in this photo, but there is a black hose coming from the top of the barrel to the bottom, left side of

the still, where the steam vapor enters the still. This is shown on the diagram in the left coumn, though.

At the

top right of the still, in the picture frame, is the license I received (just in the nick of time) from the Federal Bureau

of Alcohol, Tobacco, and Firearms. The 5 gallon glass bottle on the left is where the high proof alcohol is received and stored.

Some elses hand is on the garden hose fitting where the cooling water enters the device, and this water came from a faucet

on the building 25 meters in back of me, the Boulder City Hall. We made a little under 2 gallons of 180 proof each day, and

the total time to do this, from when the beer started boiling, was about 45 minutes. It took a little over 30 minutes to get

the water to start boiling. It initially boils at about 85 C, because the alcohol slightly lowers the boiling temperature,

but also because Boulder, Colorado is 1,500 meters above sea level. That is a hydrometer laying on the ground, to test the

proof of the alcohol. You will need a low proof one for the bear (also called a balling hydrometer) and a high proof one for

testing what comes out so you cane make some minor adjustments in the temperature settings. Control the temperature, and you

control the proof. It will vary mainly due to ambient temperature: on cold, windy days, you wont need as much water for cooling)

and due to the altitude, as mentioned above. The temperature control valve is mounted directly on the front of the wooden

support frame, just 30 cm to the right of my friends hand. The water hose is under pressure, and because there is a temperature

sensor which leads to a diaphragm on the control valve, it opens and closes very quickly in response to less than a degree

C temperature change.

If anyone wants to buy a set of plans to build their own still, I will mail them out to you,

along with 40 pages of instructions on building and running the still, for $30.00.

I am predicting a huge increase

in petrol prices in May or June, 2002, due to financial world backlash from terrorism and the War on Terrorism. This is going

to have a huge ripple effect in the World economy, and it is likely to seriously effect Asian nations worse than the economic

crises of 1997. Prices will remain high for about 6 months, or even longer if Bush starts bombing Iraq. My predictions are

based on historical trends, and I am old enough to have seen this happen a few times. (I just turned 50 this year). So, the

upside of this will be an increased public interest in ethanol and biodiesel. Sometimes it takes a crises to effect real changes.

I just hope it doesn't get too bad, but poor countries are always the hardest hit by such economic hard times.

Molasses is an economical product for making your own E85 fuel.

|

|

|

|

|

|

|