|

Huge breakthrough--or, huge mistake?

The ability to make ethanol from straw-- rice straw, wheat straw, oat straw, etc—is the modern day equivalent of the

Holy Grail or the Philosopher’s Stone. In a time when barely any new oil fields have been discovered in the past ten

year-- and a war in Iraq rages with such anarchistic abandon that it seems unlikely that anyone will be able to pump oil for

a the next several year—well, the news that we can run our cars on this “new” fuel is a breathe of fresh

air. Literally! Ethanol burns much cleaner that gasoline, and doesn’t add fossilized CO2 to the atmosphere: it is recycling

present day CO2.

However, this new development does have Greenpeace and other environmental activists worried: It involves a genetically modified

organism: a genetically engineered yeast

to convert glucose AND xylose into ethanol.

They added three genes to plain old Saccharomyces yeast so that it can break down both sugars at the same time.

They claim a 30~40% increase in yield. This could be a huge breakthrough--or a huge mistake. Xylose makes up roughly 30~40%

of celluloid materials like corn stalks, grass, wood chips, leaves, etc. In short, a yeast that feeds on xylose can feed on

almost anything in the plant kingdom.

Intensive research on cellulose conversion to ethanol previously focused on mechanical, heat and acid hydrolysis techniques,

all of which are expensive. Propagating a yeast organism, on the other hand, seems as simple as baking bread or brewing beer.

But don’t expect that we small scale distillers will be able to buy this anytime soon.

It's the property of Purdue University & they have taken a completely novel approach to marketing this patented technology.

They are “leasing” (not selling) the yeast to a Canadian company, Iogen. http://www.Iogen.ca Iogen is already

producing ethanol and selling it to Petro-Canada for mixing with gas. They are claiming 75 Gallons per ton of straw, with

roughly 2/3 of the straw being converted.

It is interesting that Iogen and Shell chose to announce this product to the world in Europe, which historically has been

actively fighting any GMO products. Just a week later in Madison, Wisconsin, the 20th annual Fuel Ethanol Workshop had over

1500 ethanol industry attendees, including Iogen-- an exhibiting company, but no mention of this breakthrough was mentioned.

Apparently, Iogen, Shell, and Petro-Canada are playing their cards close to their vests. The market for fuel ethanol is established

beyond any doubt: it is presently a 3 billion dollar/year industry. By keeping this technology to themselves, a new bio-technology

industry promises to be the new Middle East in terms of fuel supply.

The other corporate players in this announcement, DaimlerChrysler and VW, have long produced cars that will run or 85% to

100% alcohol--previously only in Brazil, but now in the US, too.

A report titled, “Genetic Engineering—Too good to go wrong?” can be found at

http://archive.greenpeace.org/comms/97/geneng/getoogoo.html

This above link lists various accidents and very dangerous and toxic side effects of genetic engineering efforts so far. An

unrelated but somewhat parallel effort to produce a GMO yeast produced very high toxic levels of a mutagenic product, methyl

glyoxal, with the potentially undesirable effect of getting loose into the food chain.

Big business stands to make billions on GMO products, especially one such as a new organism that can readily turn straw into

fuel. The Iogen press release, below notes that collaborated with Shell and Petro-Canada.

It seems the real credit goes to Dr. Nancy Ho, a Purdue scientist who made her breakthrough in 1993. No mention was made of

her or Purdue University in any of the Iogen or Shell press releases.

In terms of agriculture, if GMO organisms can be contained within the capital intensive manufacturing facilities (where trucks

hauling rice and wheat straw will come and go every day) this means that farmers will no longer burn their rice straw. This

will have an additional effect of containing CO2—nobody likes the smoke from huge field burns. But on the other hand,

if these trucks end up picking up some “hitch-hiker” organisms on their rounds, the possibility of a GMO yeast

that dissolves xylose, if it gets out into the environment, sounds like a script from a science fiction thriller.

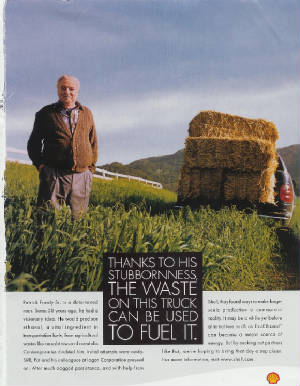

| Shell advert, June 2004 United In-Flight magazine. |

|

| Photo of Patrick Foody, Sr., Iogen Corp. |

Read the story of Butanol (another type of alcohol that makes a good fuel). We almost had a huge rice straw to alcohol plant

in Fresno in 1971.

|

|

|

|

|

|

|

|

|

CELLULOSE ETHANOL IS READY TO GO

Iogen producing world’s first cellulose ethanol fuel

Ottawa – Iogen Corporation announced today that it is producing the world’s first cellulose ethanol fuel for commercial

use. Cellulose ethanol is an ultra-low CO2 emission fuel that can be blended with gasoline and used in cars today.

“Today marks the first concrete signal of a major change coming in the fuel market,” said Iogen President, Brian

Foody. “We have always looked to better and more efficient vehicles to reduce fossil fuel consumption. Now, new advanced

fuels are ready to play a role too!”

“Canada is on the cusp of a new energy era and companies such as Iogen are showing the way,” said the Honourable

Paul Martin, Prime Minister of Canada. “Our technological expertise in clean energy will be one of the pillars of our

economic and environmental prosperity in years to come.”

“This milestone would not have been possible without the commitment, support and vision of Shell, Petro-Canada, and

the Government of Canada,” said Foody. “These organizations have shown that they are committed to bringing forward

technologies that really can make a difference.”

Iogen’s cellulose ethanol technology is a result of more than 25 years of research and development. Iogen and its partners

have committed over C$110 million, and the company owns and operates the world’s only cellulose ethanol demonstration

scale facility.

“Iogen has demonstrated that clean, renewable fuels are no longer a dream, they are a reality,” said Duncan Macleod,

Portfolio Manager of Shell Global Solutions International B.V. “We believe that the global market for bio-fuels such

as cellulose ethanol will grow to exceed $10 billion by 2012. Cellulose ethanol is a great fit with Shell’s commitment

to leadership in fuels technology and sustainable development.”

“All of us at Petro-Canada are pleased to see Iogen bringing its leading-edge cellulose ethanol technology to fruition,”

said Petro-Canada Vice-President Andrew Stephens. “We made our first investment in this technology over five years ago,

so it's fitting that Petro-Canada will be the first user of cellulose ethanol, and will be receiving the first shipment at

our Montreal refinery.”

“GM Canada welcomes Iogen’s introduction of cellulose ethanol as a very significant product development that could

make a considerable contribution to the reduction of greenhouse gas emissions,” said David Paterson, Vice-President,

General Motors of Canada. “GM’s entire portfolio of vehicles is already capable of running on a blend of 10 per

cent ethanol. We are pleased to see a leading-edge Canadian company like Iogen develop the next generation of ethanol and

we encourage its adoption in the marketplace.”

“All vehicles can use a standard blend of up to 10 per cent cellulose ethanol mixed with gasoline, with no changes required.

“Iogen’s cellulose ethanol demonstration facility is the final proving stage prior to the rollout of full-scale

commercial plants. The company is working with its partners to finalize plant locations.

“Cellulose ethanol has two unique advantages over conventional ethanol. First, the greenhouse gas emission reductions

from cellulose ethanol are three times greater than those from grain based ethanol on a life cycle basis. Second, cellulose

ethanol is made from a plentiful and renewable resource, the non-food portion of agriculture crops (e.g. straw, corn stalks

and corn cobs).”

See related article on Iogen, Shell, & Daimler Chrysler. Click here.

DEO Funds Research

According to Business Week, Dr. Nancy Ho and Purdue aren't the only players in that lucrative bioethanol arena.

"The race to create new microbes capable of fermenting the full range of sugars found in biomass has followed several

successful pathways. Dr. Lonnie Ingram at the University of Florida started with an E. coli bacterium capable of metabolizing

multiple sugars and added the ability to make ethanol-a feat for which he received U.S. Patent #5,000,000 in 1990. His work

was sponsored by the Biofuels Program and others.

Taking an approach that complements Dr. Ingram's E. coli, other DOE researchers started with the bacterium Zymomonas,

a naturally efficient ethanol-producing bacterium, and added the capability for utilizing multiple sugars. (see "Zymomonas

recognized by scientific peers,").

DOE also helped support Purdue's Dr. Nancy Ho, who started with the "industrial workhorse" for ethanol production-the

yeast Saccharomyces-and added the capability for utilizing multiple sugars.

All three organisms are now being tested by industrial partners for use in bioethanol production."

| Only 5 fett high, it makes 5 gallons/hr 190 proof |

|

|

| Robert Warren's ethanol still. |

Click on this link to learn how to build your own alcohol still.

|

|

|

|

|